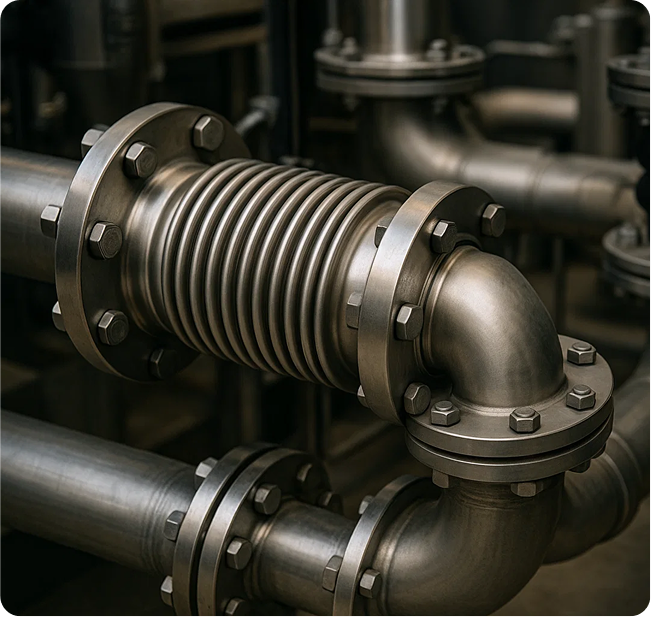

In the world of modern industry, attention often gravitates toward cutting-edge machinery and advanced automation. However, there’s a critical component operating quietly behind the scenes - metal bellows and expansion joints. That plays a pivotal role in ensuring operational efficiency and longevity.

Despite their unassuming presence, these flexible connectors are essential. Often overlooked, they don’t draw much attention until a system failure brings operations to a halt. Their function, though understated, is vital: absorbing vibrations, accommodating thermal expansion, and relieving mechanical stress across piping and equipment systems.

Neglecting these components during system design or maintenance planning can lead to significant consequences like unplanned downtime, costly repairs, and avoidable maintenance challenges. These issues not only disrupt production but also escalate operational costs and risk.

Investing in high-quality metal bellows and partnering with the right experts ensures durability, precision, and peace of mind. Because in industrial systems, it's often the smallest parts that uphold the biggest responsibilities.

That’s where Flexibel comes in. As a trusted supplier of expansion bellows and rubber joints in the UAE and GCC, Flexibel combines technical expertise with regional knowledge to deliver solutions that last. Whether it’s a custom-made joint built for a marine setup or a ready-to-use option for an industrial pipeline, our goal is simple — to help businesses keep their systems running without unwanted surprises. In this blog, we’re diving into why it actually matters to pay attention to your expansion joints — and how a little focus here can save you from a lot of trouble later. And how choosing the right supplier can save you far more than just time and money.

Before we go into the risks of neglecting them, let’s first understand what these expansion joints and industrial bellows do.

An expansion joint, also known as a bellow joint expansion, is a flexible connector which is installed in piping systems. Its purpose is to absorb dimensional changes caused by:

Flexible bellows or bellows expansion joints are designed to provide flexibility in all directions such as axial, lateral, and angular ensuring the integrity of the pipeline system while minimizing stress on connected components. In other words, they’re the shock absorbers and pressure regulators of your mechanical systems.

When bellow expansion joints are not given the attention they deserve, operations can face a domino effect of issues:

Without proper compensation for thermal expansion, pipelines can experience extreme stress which leads to cracks, ruptures, or complete system breakdowns. This means unplanned shutdowns, urgent repairs, and significant downtime in the plant and none of which are kind to your bottom line.

Ignoring wear and tear on rubber expansion joints or flexible joints means small issues are left to fester. What starts as a minor leak or vibration could eventually require entire system overhauls, significantly inflating maintenance budgets.

In high pressure or high temperature environments, failure of an expansion joint could lead to dangerous leaks or bursts. This puts not only your machinery but also your team’s safety at risk and that’s a liability no business wants.

Regulatory authorities in the Gulf Cooperation Council, especially in sectors like oil & gas, marine, and infrastructure, are bound to follow the strict adherence to quality and safety standards. Neglecting your industrial bellows could mean falling short of those standards, leading to fines or operational halts.

Even seasoned professionals may fall for these myths:

Reality: Bellows manage stress and absorb energy that would otherwise damage your system.

Reality: From rubber expansion bellows to metallic bellows, the selection must match pressure ratings, temperature conditions, and media compatibility.

Reality: Just like any component, they need inspection and replacement on a routine basis.

In a market crowded with generic products and inconsistent service, Flexibel doesn’t just deliver expansion joints, but we deliver confidence. Every joint, every bellow, every connection is backed by a deeper promise to keep your systems running efficiently, safely, and without surprises.

No two projects are the same and we treat them that way. Whether you need a metallic bellow for a high temperature power plant or a rubber joint for a chilled water line, we design each solution to match your specific operational needs. Because when the fit is right, everything works better.

We’re based in the UAE and work across the GCC, which means we’re well-acquainted with the region’s unique challenges such as extreme desert heat to the salt laden air of coastal facilities. But regional know how isn’t enough. That’s why we combine our local insight with international manufacturing standards, delivering products that are both resilient and compliant.

At Flexibel, durability isn’t optional it’s built into everything we make. Our products undergo rigorous testing and meet certified quality standards, so when we say something will perform over the long term, we mean it.

Our expansion joints and bellows are trusted by industries that can’t afford to take chances including:

Don’t wait for failure. Look out for these early warning signs:

An annual inspection and proactive replacement policy with expert input from Flexibel can significantly extend your system’s life.

When it comes to operational efficiency, every part matters. Ignoring or underestimating the role of expansion joints, bellows, and flexible connectors is a risk no industrial operation should take.

With Flexibel, you're not just buying a component; you're investing in peace of mind, operational safety, and long-term profitability.

Let our team help you engineer reliability into your system one bellow at a time.