Industries we Serve

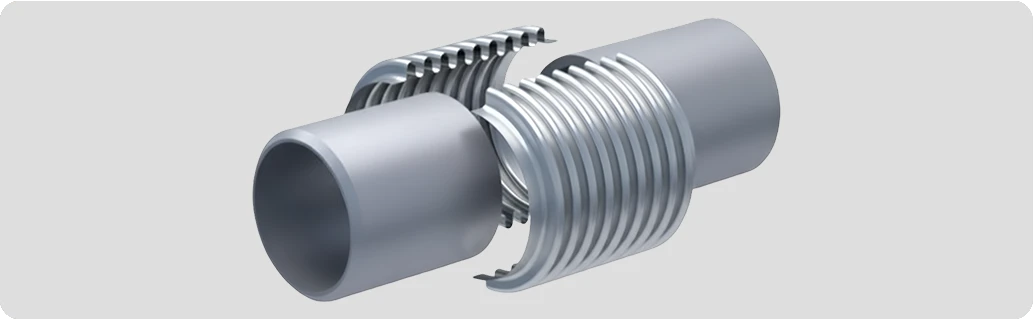

At Flexibel, our precision engineered expansion joints & metal bellows are designed to meet the stringent demands of today’s most challenging industrial environments. By compensating for thermal growth, vibration, misalignment and pressure fluctuations our products protect critical equipment along with extending service life and minimize costly downtime. Supported by in house manufacturing, advanced quality controls and decades of engineering expertise, we deliver bespoke bellows solutions that perform reliably whether you’re offshore or underground or in the heart of a processing plant.

From concept a& material selection through fabrication and on-site installation, Flexibel partners with you at every step to ensure a perfect fit for your piping or ductwork system.

Onboard systems such as exhaust lines, scrubbers, boilers, and condensate drains operate in confined spaces under constant vibration, fluctuating pressures, and seawater corrosion. Flexibel supplies compact axial and universal bellows made from stainless steels like 304L, 316L, and 321H, with multi-ply construction and inner sleeves where required. For high exhaust temperatures or aggressive gases, Inconel and Hastelloy are applied. Each unit is fatigue-tested for leak-tight reliability in critical marine environments.

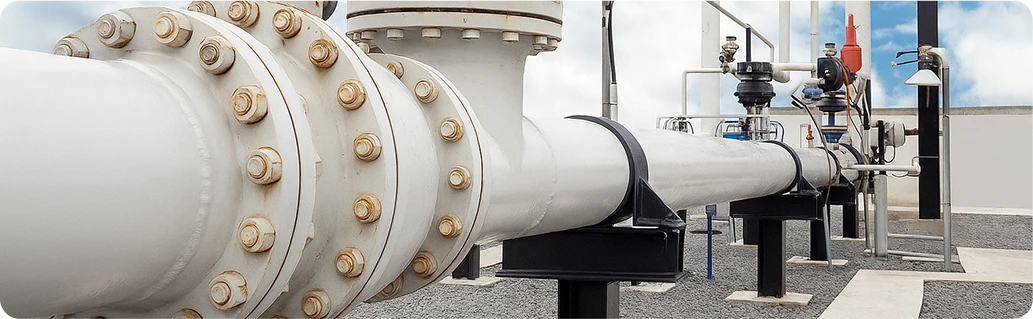

Refineries, petrochemical plants, and offshore platforms require joints that manage thermal growth, pulsation, and aggressive hydrocarbons. Typical uses include compressor discharges, turbine exhausts, flare systems, and cross-country pipelines. Flexibel provides axial, hinged, gimbal, and pressure-balanced designs engineered to EJMA standards. Materials range from 316L and 321H stainless steels up to Inconel 625 and Hastelloy C-276 for sour service. Every joint is built for fatigue resistance and long-term sealing under continuous operation.

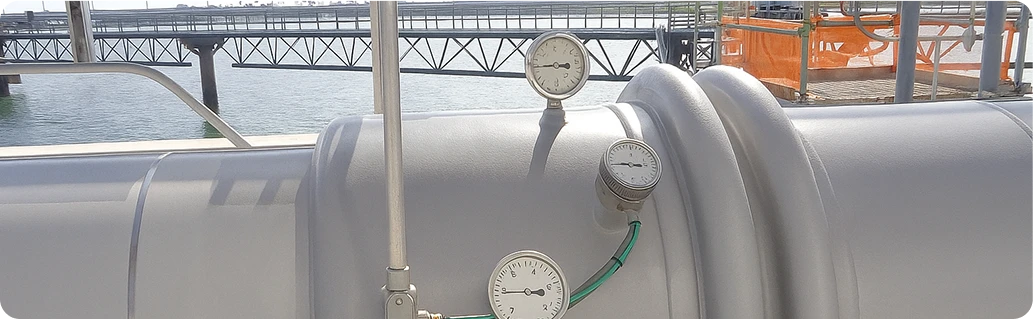

Cryogenic service demands joints that withstand temperatures as low as –165 °C while ensuring zero leakage. Applications include cold box piping, LNG transfer lines, and loading arms. Flexibel designs multi-ply stainless steel bellows with liners for turbulence control and optional insulation layers to prevent frost build-up. For extreme cold resilience, Inconel is specified for its ductility at cryogenic temperatures. Each joint is helium-leak and pressure tested for flawless sealing.

Boilers, HRSG units, turbines, and flue gas systems impose high thermal stresses and vibration. Expansion joints are installed in steam lines to absorb axial growth and in ducts to accommodate large multi-directional movements. Flexibel manufactures metal bellows for high-pressure steam service and fabric expansion joints for flue gas ducting. Design challenges such as rapid cycling, fly ash erosion, and restricted spaces are addressed through tailored ply thickness, inner sleeves, and material upgrades including 321H stainless and Inconel.

Blast furnaces, converters, and rolling mills generate high heat, abrasive dust, and strong vibration. Expansion joints protect piping in off-gas lines, steam circuits, and flue ducts. Flexibel delivers axial and universal bellows in stainless steels, refractory-lined designs for flue gas, and heavy-duty fabric joints for large ducts. Where extreme temperatures demand, 321H or Inconel alloys are specified. Reinforced multi-ply designs extend fatigue life in harsh steelmaking conditions.

Process piping and ductwork in chemical plants are exposed to corrosive fluids, solvents, and aggressive vapors. Expansion joints are installed in reactors, heat transfer systems, and scrubber ducts to absorb movement and prevent leakage. Flexibel designs joints from stainless steels such as 316L and 321H, with advanced materials including Hastelloy C-276 or Inconel for highly aggressive environments. Both metal and fabric joints are supplied, ensuring corrosion resistance and long-term durability in continuous operation.

Cement kilns, coolers, and fans subject joints to dust, high temperatures, and continuous motion. Fabric expansion joints are used in large ducts to absorb misalignment and vibration, while metal bellows joints handle high-pressure steam or process lines. Stainless steel with liners, or high-temperature fabrics, are selected depending on service conditions. Each design provides durability against dust abrasion and thermal cycling, helping maintain uninterrupted plant operations.

Nuclear facilities require expansion joints with the highest safety margins, operating under high temperature, pressure, and radiation. Applications include reactor coolant circuits, feedwater lines, and turbine steam systems. Flexibel designs metal bellows to EJMA and ASME methodologies, engineered for fatigue life and leak-tight performance. Standard materials include 321H stainless steel, with Inconel alloys specified where superior creep resistance and high-temperature stability are required. All joints undergo rigorous inspection and testing to meet nuclear-grade reliability.

FCCUs expose joints to extreme heat, abrasive catalyst flow, and continuous pressure shifts. Expansion joints are installed in reactor and regenerator lines, where refractory-lined bellows protect the metal from direct contact with hot catalyst and reduce wall temperatures. Universal and hinged designs are used to absorb axial and lateral movements. Materials such as 321H stainless steel and Inconel provide stability under high thermal loads. Abrasion-resistant designs ensure long service life in refinery operations.

Valves experience frequent cycling and vibration that can overstress piping connections. Expansion joints are integrated in valve assemblies and test systems to absorb motion, maintain alignment, and ensure seal integrity. Compact axial and angular bellows are most common, made from 316L stainless steel for general service or Inconel and Hastelloy for corrosive or high-temperature duty. Precision welds and fatigue-tested designs guarantee performance under repeated valve actuation.

Differential thermal expansion between shells, headers, and tubes in heat exchangers generates significant stress. Expansion joints relieve this stress, preventing tube damage and leakage. Toroidal and universal bellows are typically applied in these systems. Challenges include continuous thermal cycling, vibration, and space constraints. Flexibel supplies stainless steel bellows (321H standard) and Inconel where elevated temperatures or corrosive media are present. Each unit is engineered to maintain seal integrity and extend exchanger service life.

Propulsion systems, cryogenic storage, and hydraulic circuits in aerospace require expansion joints that are lightweight yet capable of withstanding vibration and extreme temperature swings. Flexibel supplies axial and toroidal bellows manufactured in advanced alloys such as Inconel, Hastelloy, and titanium, selected for high strength-to-weight ratio and fatigue resistance. Each joint is engineered for high cycle life and rigorously tested for leak-tightness, supporting mission reliability in demanding aerospace environments.

Engines and exhaust systems in vehicles are exposed to vibration, heat, and road-induced motion. Expansion joints are applied in exhaust manifolds, catalytic converter connections, turbocharger outlets, and EGR systems. Axial bellows are most common, designed for millions of fatigue cycles. Stainless steels 304L and 321H are standard, while Inconel is specified for high-performance engines. Joints are tested to reduce noise, absorb vibration, and extend vehicle service life under continuous operation.

Cranes and dredgers handling heavy loads and hydraulic systems operate under constant motion and saltwater exposure. Expansion joints are installed in hydraulic lines, slurry piping, and pump discharge systems to absorb vibration, misalignment, and shock loads. Flexibel manufactures corrosion-resistant bellows in 316L stainless, duplex steels, or Inconel where seawater and abrasion resistance are required. Reinforced ends and liners are incorporated for durability in offshore and dredging applications.

Vacuum systems require absolute leak-tightness under continuous cycling. Expansion joints are applied in semiconductor fabs, laboratory systems, and chemical processing plants to accommodate misalignment, vibration, and thermal shifts. Axial bellows are typically used, engineered from thin-wall stainless steels for flexibility and tested with helium to guarantee leak-tightness. For ultra-clean or corrosive service, Hastelloy or Inconel materials are applied. Each unit is precision-manufactured to maintain integrity in high vacuum environments.