Reinforced

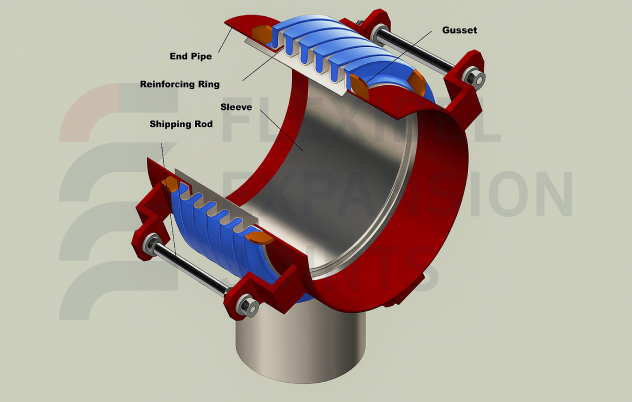

A heavy-duty expansion joint enhanced with reinforcing rings to withstand higher internal pressures and provide added stability compared to standard designs.

Enquire NowThe Metallic Reinforced Expansion Joint incorporates reinforcing rings (hollow, solid, welded, or machined types) around the bellows to increase pressure resistance and improve load distribution. This construction allows the joint to handle more demanding conditions while still accommodating axial, lateral, and limited angular movements. Available with weld ends, fixed flanges, or loose flanges, it is particularly suited for high-pressure or critical service applications.

Size Range (DN)

DN50 – DN5000

Materials

SS304 / SS316L / SS321 / Inconel / Hastelloy / others on request

Movements

Axial (primary), plus Lateral & Angular

Pressure Rating

Up to 100 bar (higher on request)

Temperature Range

–196°C to +800°C (depending on material)

The Metallic Reinforced Expansion Joint incorporates reinforcing rings (hollow, solid, welded, or machined types) around the bellows to increase pressure resistance and improve load distribution. This construction allows the joint to handle more demanding conditions while still accommodating axial, lateral, and limited angular movements. Available with weld ends, fixed flanges, or loose flanges, it is particularly suited for high-pressure or critical service applications.

Size Range (DN)

DN50 – DN5000

Materials

SS304 / SS316L / SS321 / Inconel / Hastelloy / others on request

Movements

Axial (primary), plus Lateral & Angular

Pressure Rating

Up to 100 bar (higher on request)

Temperature Range

–196°C to +800°C (depending on material)

Typical use case: Widely used in high-pressure process lines where standard joints may not provide sufficient stability, such as boiler feedwater systems and refinery pipelines.

Other applications include:

increase pressure resistance and load distribution

Flow Liner / Inner Sleeveprotects bellows from abrasive or turbulent media

Limit Rodsprevent over-compression/extension

Adjustment Rodsassist in installation and alignment

Gusset Platesprovide added reinforcement at structural connection points

End Connectionsweld ends, fixed flanges, or loose flanges