Twin Sphere Expansion Joint

A flexible molded rubber joint with a twin-sphere design, offering greater deflection capability and lower spring rates than single-sphere joints. Ideal where higher flexibility is required in compact piping layouts.

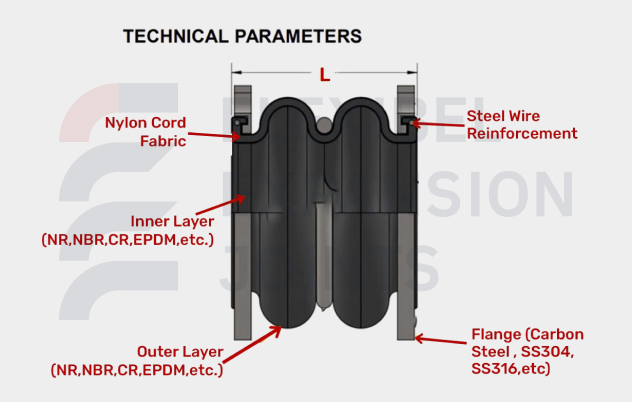

Enquire NowThe Rubber Twin Sphere Expansion Joint is constructed with two adjacent spherical arches of reinforced elastomer. This geometry provides increased movement absorption, reduced stiffness, and improved vibration/noise damping compared to single-sphere types. Typically supplied with floating flanges or clamped ends, twin-sphere joints are suited for piping systems requiring higher flexibility in shorter lengths.

Size Range (DN)

DN25 – DN600 (larger on request)

Materials (Elastomer)

Natural Rubber, EPDM, Nitrile, Neoprene, Hypalon, PTFE-lined on request

Reinforcement

Nylon tire cord with steel wire

Movements

Greater Axial, Lateral & Angular deflection vs. single sphere

Pressure Rating

PN10 – PN16 (higher on request)

Temperature Range

–20°C to +120°C (up to +150°C with special elastomers/PTFE lining)

The Rubber Twin Sphere Expansion Joint is constructed with two adjacent spherical arches of reinforced elastomer. This geometry provides increased movement absorption, reduced stiffness, and improved vibration/noise damping compared to single-sphere types. Typically supplied with floating flanges or clamped ends, twin-sphere joints are suited for piping systems requiring higher flexibility in shorter lengths.

Size Range (DN)

DN25 – DN600 (larger on request)

Materials (Elastomer)

Natural Rubber, EPDM, Nitrile, Neoprene, Hypalon, PTFE-lined on request

Reinforcement

Nylon tire cord with steel wire

Movements

Greater Axial, Lateral & Angular deflection vs. single sphere

Pressure Rating

PN10 – PN16 (higher on request)

Temperature Range

–20°C to +120°C (up to +150°C with special elastomers/PTFE lining)

Typical use case: Installed in tight piping layouts where maximum movement absorption is required within a short overall length, such as pump discharge lines and compact HVAC systems.

Other applications:

carbon steel, galvanized, or stainless steel (standard or full-faced)

Control Rodsrecommended to limit over-extension in high movement cases

Inner Liners & External Coversfor abrasive service or outdoor installations

Vacuum Support Ringsavailable for negative pressure applications