Jacketed

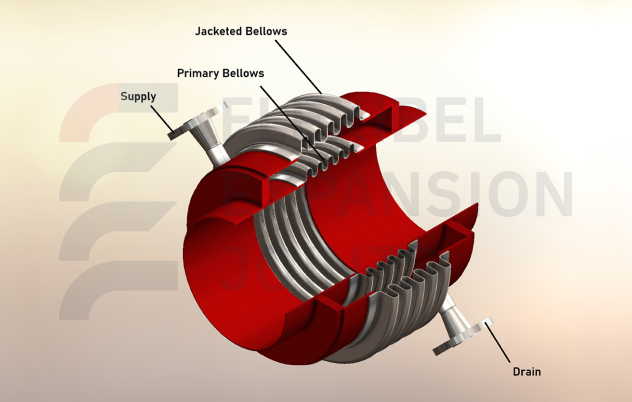

A specialized expansion joint featuring a double-wall construction, with an external jacket that ensures uniform heating or cooling of the media within the bellows and pipeline.

Enquire NowThe Metallic Jacketed Expansion Joint consists of an inner bellows and an outer jacket, through which a heating or cooling medium (such as steam, oil, or water) is circulated. This construction maintains a controlled temperature inside the main pipeline, preventing condensation, solidification, or crystallization of process media. Jacketed joints are supplied with weld ends, fixed flanges, or loose flanges, and can be customized with liners and insulation depending on process requirements.

Size Range (DN)

DN50 – DN5000

Materials

SS304 / SS316L / SS321 / Inconel / Hastelloy / others on request

Movements

Axial (primary), plus limited Lateral & Angular

Pressure Rating

Up to 100 bar (higher on request)

Temperature Range

–196°C to +800°C (depending on material and heating medium)

The Metallic Jacketed Expansion Joint consists of an inner bellows and an outer jacket, through which a heating or cooling medium (such as steam, oil, or water) is circulated. This construction maintains a controlled temperature inside the main pipeline, preventing condensation, solidification, or crystallization of process media. Jacketed joints are supplied with weld ends, fixed flanges, or loose flanges, and can be customized with liners and insulation depending on process requirements.

Size Range (DN)

DN50 – DN5000

Materials

SS304 / SS316L / SS321 / Inconel / Hastelloy / others on request

Movements

Axial (primary), plus limited Lateral & Angular

Pressure Rating

Up to 100 bar (higher on request)

Temperature Range

–196°C to +800°C (depending on material and heating medium)

Typical use case: Extensively used in process lines transporting viscous or temperature-sensitive fluids, where continuous heating or cooling prevents media from solidifying or depositing inside the pipe.

Other applications include:

circulates heating or cooling medium around the bellows

Flow Liner / Inner Sleeveprotects bellows from process media turbulence

End Connectionsweld ends, fixed flanges, or loose flanges

Insulation Layers –minimize heat loss for temperature-sensitive applications

Support Rods / Limit Rodsprotect against over-compression or over-extension