Single Sphere Expansion Joint

A compact, highly flexible molded rubber joint with spherical design. Ideal for absorbing vibration, noise, and multi-directional movements. Available in full-faced flange variation for superior sealing and flange protection.

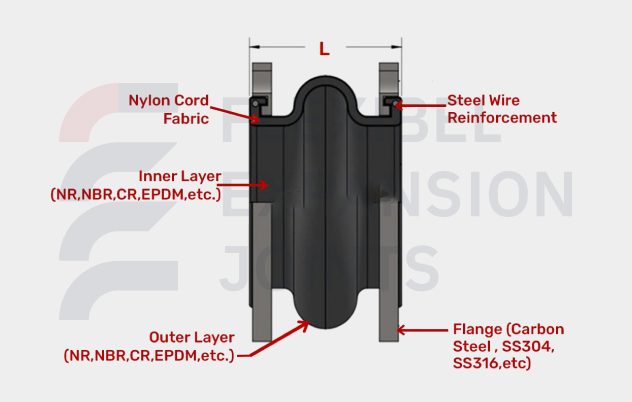

Enquire NowConstructed from a single elastomeric sphere reinforced with nylon/steel cord, fitted with flanged or clamped ends. The spherical arch provides high flexibility, minimizes turbulence, and absorbs axial, lateral, and angular deflections. The full-faced flange type improves gasket coverage and sealing reliability in critical installations.

Size Range (DN)

DN25 – DN3000

Materials (Elastomer)

Natural Rubber, EPDM, Nitrile, Neoprene, Hypalon, PTFE-lined on request

Reinforcement

Nylon tire cord with steel wire

Movements

Axial, Lateral, Angular

Pressure Rating

PN10 – PN25 (up to PN40 on request)

Temperature Range

–20°C to +120°C (up to +150°C with special elastomers/PTFE lining)

Constructed from a single elastomeric sphere reinforced with nylon/steel cord, fitted with flanged or clamped ends. The spherical arch provides high flexibility, minimizes turbulence, and absorbs axial, lateral, and angular deflections. The full-faced flange type improves gasket coverage and sealing reliability in critical installations.

Size Range (DN)

DN25 – DN3000

Materials (Elastomer)

Natural Rubber, EPDM, Nitrile, Neoprene, Hypalon, PTFE-lined on request

Reinforcement

Nylon tire cord with steel wire

Movements

Axial, Lateral, Angular

Pressure Rating

PN10 – PN25 (up to PN40 on request)

Temperature Range

–20°C to +120°C (up to +150°C with special elastomers/PTFE lining)

Typical use case: Installed at pump suction and discharge lines to isolate vibration and protect connected equipment.

Other applications: HVAC and chilled water systems, desalination plants, power plants, oil & gas utilities, and marine piping.

Full-faced flange type: Used where enhanced sealing is required, e.g., chilled water, chemical transfer, or offshore systems.

carbon steel, galvanized, or stainless steel (standard or full-faced)

Control Rodsprevent over-extension in restrained systems

Vacuum Support Ringsfor negative pressure service

Inner Liners & External Coversfor abrasive or outdoor environments