Externally Pressurized

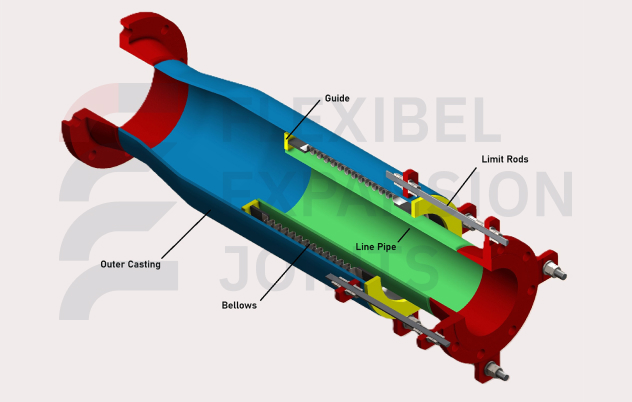

A specially engineered expansion joint where the pressure acts on the outside of the bellows, enabling very large axial movements while preventing squirm or instability.

Enquire NowThe Metallic Externally Pressurized Expansion Joint uses a unique design in which the process pressure is applied externally to the bellows element rather than internally. This allows the joint to absorb long axial movements without the risk of squirm, buckling, or premature fatigue. Typically supplied with butt weld ends or flanged connections, these joints are well-suited for long pipeline runs requiring high reliability and stability under pressure.

Size Range (DN)

DN50 – DN5000

Materials

SS304 / SS316L / SS321 / Inconel / Hastelloy / others on request

Movements

Axial (long stroke)

Pressure Rating

Up to 100 bar (higher on request)

Temperature Range

–196°C to +800°C (depending on material)

The Metallic Externally Pressurized Expansion Joint uses a unique design in which the process pressure is applied externally to the bellows element rather than internally. This allows the joint to absorb long axial movements without the risk of squirm, buckling, or premature fatigue. Typically supplied with butt weld ends or flanged connections, these joints are well-suited for long pipeline runs requiring high reliability and stability under pressure.

Size Range (DN)

DN50 – DN5000

Materials

SS304 / SS316L / SS321 / Inconel / Hastelloy / others on request

Movements

Axial (long stroke)

Pressure Rating

Up to 100 bar (higher on request)

Temperature Range

–196°C to +800°C (depending on material)

Typical use case: Widely used in long pipeline runs that require absorption of very large axial thermal expansions, such as in district heating, cryogenic transfer lines, or steam distribution networks.

Other applications include:

transfers pressure load outside the bellows for stability

Flow Liner / Inner Sleeveprotects against abrasive or turbulent flow

End Connectionsweld ends, fixed flanges, or loose flanges

Limit Rodsprevent excessive stroke or over-compression

External Covers / Shroudssafeguard against mechanical damage