PTFE-Lined Expansion Joint

A rubber expansion joint with an internal PTFE lining, designed to handle highly aggressive chemicals, solvents, and corrosive media while maintaining the flexibility and vibration-damping benefits of rubber.

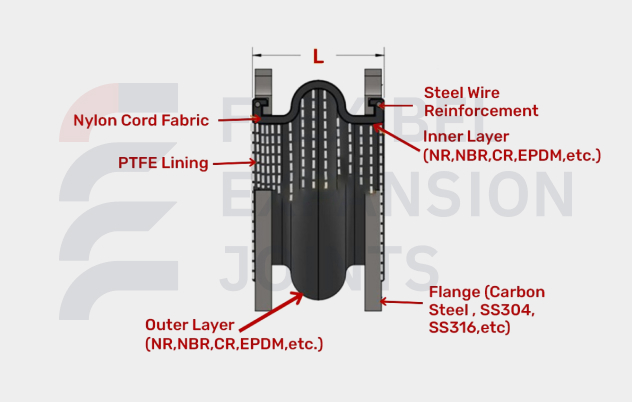

Enquire NowThe PTFE-Lined Rubber Expansion Joint combines an elastomeric body (EPDM, Neoprene, Nitrile, etc.) with a seamless PTFE liner molded or bonded inside. The PTFE liner provides exceptional chemical resistance and protects the elastomer from attack, while the rubber body allows axial, lateral, and angular flexibility with excellent vibration and noise absorption. Typically supplied with flanged ends, these joints are used where standard elastomers cannot withstand the conveyed medium.

Size Range (DN)

DN25 – DN1200 (larger on request)

Materials (Elastomer)

EPDM, Nitrile, Neoprene, Nitrile, Natural Rubber (outer body)

Liner

Virgin PTFE (white), available in FDA-approved grades

Reinforcement

Nylon tire cord with steel wire

Movements

Axial, Lateral & Angular

Pressure Rating

PN10 – PN16 (up to PN25 on request)

Temperature Range

–20°C to +150°C (depending on outer rubber & PTFE grade)

The PTFE-Lined Rubber Expansion Joint combines an elastomeric body (EPDM, Neoprene, Nitrile, etc.) with a seamless PTFE liner molded or bonded inside. The PTFE liner provides exceptional chemical resistance and protects the elastomer from attack, while the rubber body allows axial, lateral, and angular flexibility with excellent vibration and noise absorption. Typically supplied with flanged ends, these joints are used where standard elastomers cannot withstand the conveyed medium.

Size Range (DN)

DN25 – DN1200 (larger on request)

Materials (Elastomer)

EPDM, Nitrile, Neoprene, Nitrile, Natural Rubber (outer body)

Liner

Virgin PTFE (white), available in FDA-approved grades

Reinforcement

Nylon tire cord with steel wire

Movements

Axial, Lateral & Angular

Pressure Rating

PN10 – PN16 (up to PN25 on request)

Temperature Range

–20°C to +150°C (depending on outer rubber & PTFE grade)

Typical use case: Extensively used in chemical process lines where aggressive acids, alkalis, or solvents are present, ensuring safe and reliable operation.

Other applications:

stainless steel, galvanized, or lined flanges as required

Control Rodsfor restrained installations and controlled movement

External Coversprotect rubber body from UV, ozone, or weathering

Vacuum Support Ringsavailable for negative pressure service

Custom PTFE Gradesanti-static or conductive liners for special service