Single/Single Tied

A compact and common expansion joint designed to absorb axial thermal movements in pipelines. Its simple single-bellows construction makes it one of the most widely used joint types in piping systems.

Enquire NowTypical use case: Best suited for long, straight pipeline runs such as steam lines, district heating, or exhaust ducts, where controlled axial thermal expansion must be absorbed without altering the pipeline’s flow direction.

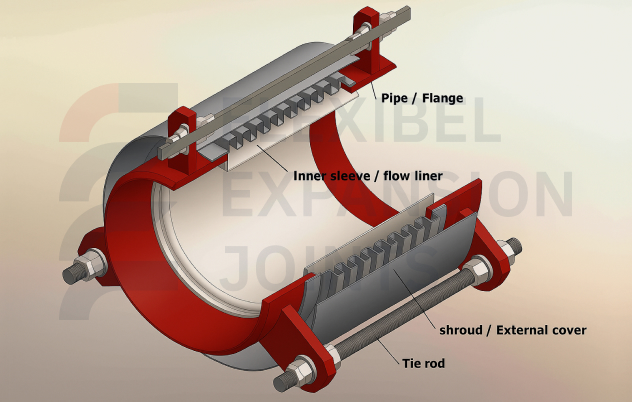

protects the bellows from external damage

Flow Liner / Inner sleevesafeguards against erosion from turbulent or abrasive flow

Tie Rodcontrol pressure thrust where required

Limit Rodprevent over-extension or over-compression of the bellows

Adjustment rodassist in length setting before installation

End Connectionsweld ends, fixed flanges, or loose flanges depending on system design