Bellow joint expansions might not look like much, but they do a big job in piping systems. They take in all the shaking, shifting, and expanding that happens when temperatures change, or systems run under pressure. Without them, pipes would wear out a lot faster. They also help cut down on noise and fix minor misalignments.

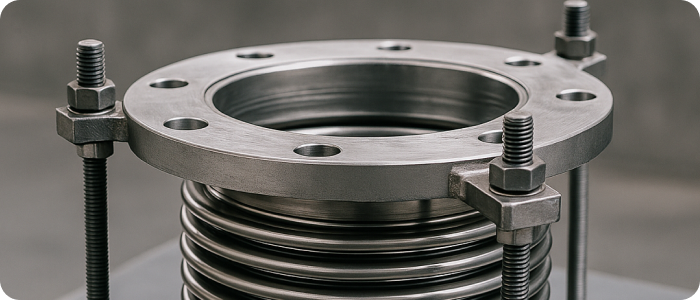

These joints have become more important than ever with industries getting more advanced keeping things running smoothly without anyone really noticing. A bellow joint expansion also known as an expansion bellow or just a bellow is basically a flexible connector that sits between two sections of piping. Its job? To handle movement in all directions whether it’s stretching lengthwise, shifting side to side, or bending at an angle. This makes it perfect for absorbing the stresses and shifts that naturally happen in any active system. You’ll usually find these joints made from stainless steel or tough rubber materials, depending on where they’re being used. The material choice really comes down to the environment some need to handle high heat, other chemicals, and some just need to last a long time under pressure.

Imagine a few pipes with no flexibility every time the temperature changes or pressure builds up, the pipes are forced to take the hit. Over time, that constant stress can cause cracks, leaks, or even full-on failures. That’s where expansion bellows come in. Whether it’s a high rise building or an offshore oil rig, these joints quietly protect the system from within.

Here’s why rubber expansion joints and flexible connectors are becoming real game changers for today’s structures:

Thermal Compensation: Pipes naturally expand when it is exposed to heat or high pressure, and without room to move, they tend to push against each other. Bellows absorb that thermal expansion, allowing the system to breathe without damage. It’s like giving your piping a built-in safety valve that prevents warping or breakage. Without a joint bellow, pipelines would warp or break.

Vibration Damping: Heavy equipment vibrations can cause joint fatigue. Bellows absorb this motion.

Noise Reduction: By softening vibration, they reduce sound transmission ideal for hospitals and office buildings.

Misalignment Adjustment: Buildings settle over time. Bellow joint expansions allow slight shifts without damage.

As a trusted manufacture of Bellow Expansion Joints, Flexibel® is not just manufacture parts but they solving problems before some mishap may happen.

When it comes to bellow joints, the material you choose can make all the difference. At Flexibel, we offer a variety of options, each designed for specific needs, whether you’re dealing with high heat, chemicals, or just the great outdoors.

Natural Rubber – This one’s your go-to if you’re working with low-pressure systems and nothing too corrosive. Reliable and straightforward.

Neoprene – If you’re putting your joints outside, Neoprene’s the way to go. It holds up well against the weather, making it great for outdoor setups like HVAC units on rooftops.

EPDM – For environments that get a bit hotter or involve chemicals, EPDM is a solid choice. You’ll find it used a lot in HVAC systems where both heat and chemical exposure are part of the game.

Nitrile Rubber – If your system handles oil, you’ll want nitrile. It’s built to resist oil-based substances, so it’s perfect for fuel lines or anything dealing with petroleum.

Silicone – Need something that can handle high heat or even food-grade environments? Silicone is heat-resistant, flexible, and safe enough for food processing or pharma applications.

Picking the right expansion bellow isn’t just about grabbing one off the shelf. There are a few key things you need to look at to make sure it’ll do the job and do it well over time.

Is your pipe shifting up and down, side to side, or maybe even twisting a bit? The type of movement matters big time when choosing the right joint.

Some systems get freezing cold, others are running red hot. Your bellow needs to be made from a material that can take the heat or the chill without wearing out fast.

Whether you’re pushing water, steam, chemicals, or gas through your pipes, the joint has to handle that pressure without breaking a sweat.

It sounds simple, but it’s easy to overlook your joint needs enough room to flex and move. If it’s squeezed into a tight corner, it won’t last long.

At Flexibel, we take all of this into account before we recommend a solution. Every bellow joint we provide is tailored to your setup, so it fits just right and keeps things running smoothly for the long haul.

To ensure that you’re getting the right expansion bellow, there are several factors which must be evaluated:

We provides custom solutions after analyzing these exact conditions, making sure every bellow joint expansion fits like a glove.

Just like any hardworking part of a system, bellow joint expansions needs a maintenance to keep doing their job right. They're built tough, sure but nothing lasts forever, especially when exposed to constant movement, pressure, and heat.

If you've ever dealt with a failed pipe system, you know it's not something you want to go through twice. Even though bellows expansion joints are built to last, they’re still under constant pressure literally. Over time, the wear starts to show. From what we've seen in the field, small warning signs often go unnoticed until they cause real trouble. It could be something as subtle as:

- A tiny bulge that wasn't there last month

- The rubber feeling a bit too brittle (or oddly soft)

- A slight drop in pressure that seems like no big deal

- But these are the early indicators that a joint’s on its way out.

As a general rule, most rubber expansion joints should be looked at seriously after 5 years, and by 10, it's usually time for a swap though heavy-use environments might need attention sooner.

Regular inspections aren’t just about ticking a box. They’re about avoiding that 3 AM emergency call, the shutdown that throws off your whole week, or the cost of replacing an entire section when a single joint could’ve been replaced months ago.

At Flexibel we work closely with clients to set up inspection schedules that make sense for their operations. We’d rather help you fix a small issue today than see you deal with a big one tomorrow.

If you have spent any time around industrial area or infrastructure projects, you know it's not always the heavy machines or towering structures that keep things going. Sometimes, it is the little things doing the heavy lifting behind the scenes like the bellow joint expansion. Whether it’s managing pressure in a turbine line or handling thermal shifts in a high rise’s Heating, ventilation, and air conditioning system, these compact joints quietly keep everything intact. They don’t get the spotlight, but without them, even the best designed systems would eventually crack under pressure. That's why working with the right supplier really matters.

At Flexibel Expansion Joints, it is not just about manufacturing parts but it is about solving problems before they some mishap may happen. We take the time to understand your setup, your challenges, and what success looks like for your project.

In a world where downtime is expensive and reliability is everything, it’s the smart, quiet solutions like expansion bellows from people who know their craft that keep your systems moving and your team focused on what matters.