Pipelines keep modern industry alive. Pipelines carry steam, water, oil, chemicals, and gases through refineries, power stations, and processing plants, pretty much anything an industrial system needs to run.

Pipelines keep modern industry alive. Pipelines carry steam, water, oil, chemicals, and gases through refineries, power stations, and processing plants, pretty much anything an industrial system needs to run.

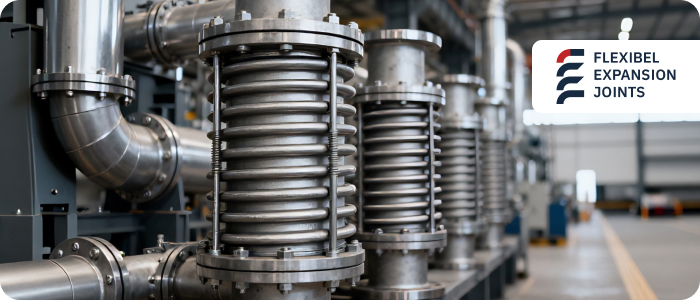

But let’s not forget the ultimate truth that a pipeline is never at rest. Heat stretches it. Cold tightens it. Machinery rattles it with constant vibrations. Pressure changes push and pull until the metal feels the strain. If nothing absorbs this then both the pipe and the equipment tied to it begin to wear down. This is the problem expansion joints were built to solve.

They don’t look like much, and nobody puts them on display. Yet without expansion joints, the system collapses. They take the movement, the stress, the shock, and keep it from spreading to costly machinery.

Take expansion joints out of the picture and you get leaks, unplanned shutdowns, and repair costs that eat into margins. In plants where uptime and safety are everything, a solid expansion joint system is what keeps the operation steady.

At their core, industrial expansion joints are flexible connectors installed in piping systems or ducts. Their role is to compensate for thermal expansion, absorb vibration, and ease the mechanical strain between sections of pipe or between equipment and the pipe.

Different designs serve different purposes:

Whatever the type, the main job doesn’t change, they take strain off the piping and protect the connected gear such as pumps, compressors, and vessels.

Walk through two plants side by side and you’ll see it immediately, no twin copies exist in this industry. A refinery built under a blistering desert sun wrestles with problems that a chemical facility along a damp, salt-heavy coast would never imagine. Off-the-shelf parts pretend to serve both, but reality proves otherwise. That mismatch is the reason expansion joint solutions aren’t just optional add-ons; they’re often the only approach that makes sense.

This is where an experienced expansion joint manufacturer becomes valuable. They don’t just sell a product; they engineer a fit-for-purpose solution.

See Also: Quality Manufacturer of Bellows Expansion Joints for Modern Industries

Expansion joints aren’t one-size-fits-all. Each design serves a very particular role. Below are the most common categories you’ll find in industrial piping systems.

1. Metal Expansion Joints: Made of stainless-steel bellows, these are designed for durability under demanding conditions. Subtypes include:

You’ll see them a lot in power plants, refineries, and chemical facilities because those setups can’t risk high stress on the pipework.

2. Rubber Expansion Joints: These are molded from elastomers and reinforced with fabric or metal. Variants include:

Rubber joints are best suited to HVAC, water treatment, and other systems where vibration and noise suppression are the main considerations.

3. Fabric Expansion Joints: These joints use layered fabrics and insulation, which makes them light and flexible. They’re mostly used on gas turbines, exhaust lines, or large ductwork where a metal or rubber joint would be too heavy to make sense.

Each sector that hinges on constant flow relies on expansion joints. Some examples are listed below:

Designing the right joint involves more than picking a catalog number. Engineers evaluate:

A good expansion joint supplier doesn’t just sell a product. They study the system, run calculations, and propose a design that prevents failures before they happen.

Learn more: Overlooking Industrial Joints and Bellows

The payoffs show up in different ways, better performance, safer operation, and lower costs over time.

Top benefits include the following:

For operators, all of this adds up to lower costs and more reliable day-to-day operation.

Picking the right partner is just as important as the product. Flexibel Expansion Joints locally manufactured in UAE has the know-how and the product range to match, supplying metal, rubber, and fabric joints for heavy-duty applications. The focus is on solid design and materials that don’t quit under pressure. Beyond manufacturing, the company stands out as an expansion joint supplier that also helps plants keep running with maintenance services, from routine inspection and repair to urgent on-site work when a system goes down.

By working with a dedicated team like Flexibel Expansion Joints, operators gain peace of mind knowing that their piping systems are protected by more than just hardware, they’re supported by expertise.

As a trusted manufacture of Bellow Expansion Joints, Flexibel® is not just manufacture parts but they solving problems before some mishap may happen.

Pipelines are never still, they shift, stretch, contract, and sometimes shake under pressure. Without the right safeguards, that constant motion can wear systems down fast. Industrial expansion joints step in as quiet protectors, keeping operations safe and efficient while cutting the risk of expensive breakdowns.

Different challenges call for different answers: metal expansion joints handle the extremes of steam and pressure, rubber expansion joints absorb vibration before it spreads, and fabric expansion joints take on the wide movement of massive ducts. When standard parts don’t measure up, custom expansion joint solutions keep critical systems running with the reliability industries depend on.

That’s where Flexibel Expansion Joints makes its mark. With strong expertise and locally manufactured in UAE, support that carries through design, installation, and expansion joint inspection and repair, we offer more than just components, we offer peace of mind to industries that cannot afford failure.