The role of expansion joints is to ensure that industrial piping systems remain safe, efficient and long-lasting.

When transporting liquids or gases (steam), pipelines are subjected to various temperature and pressure changes; therefore, they will always expand, contract, and vibrate with time or due to environmental conditions. If there is no method of providing compensation to allow for this movement, the result will be either missed or damaged components of the pipeline (pipe stress, leaks, etc.), or mechanical equipment will be negatively affected (wear, machine-related accidents). In the event that the aforementioned occurs, complete failure can occur.

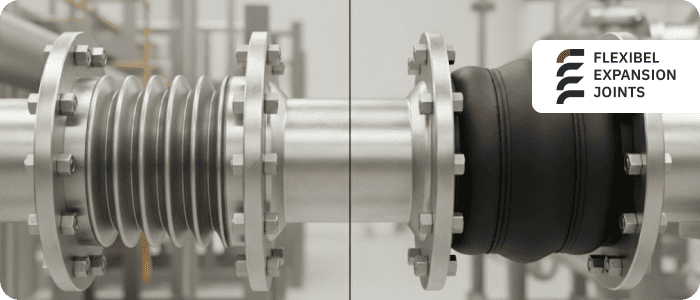

Of the types of expansion joints used in the industry today, metal expansion joints and rubber expansion joints are two of the most common approaches to addressing these issues. Depending on your application and operational conditions, either one may be appropriate. When selecting between these two types of expansion joints, the metal expansion joint and the rubber expansion joint, the choice will have an impact upon performance, safety, and long-term maintenance costs.

This blog article will provide a comprehensive overview of both types of expansion joints by comparing their material construction, mechanical/thermal performance, advantages, limitations, and most appropriate application use cases.

Metal expansion joints, known as metallic expansion Joints or, by their alternate name, Metallic Joints, are created from thin-walled metal bellows produced of stainless steel or special metal alloys. The design of these flexible components allows them to absorb both lateral and angular movement, as well as axial (linear) displacement created by thermal expansion, vibration, or misalignment, which occur in piping systems.

Industrial applications of these components include: Power Plants, Refineries, Petrochemical Plants, Steam Lines, and other products with high pressures and/or high temperatures. The combination of their ability to withstand high levels of stress and the durability of the materials utilized affords considerable value to the user of the metallic expansion joint in today's demanding industrial environments.

Read More: Guide To Metal Expansion Joints: Design, Uses & Advantages

Flexible connectors eliminate excessive vibration, noise and allow for minor movement throughout pipes (piping), whereas Rubber Expansion Joints, also include rubber expansion bellows, the rubber flexible joint and the rubber bellow joint, that can be used Hand-in-Hand with various systems.

In fact, due to their unmatched quality and performance, there are hundreds of manufacturers like Flexibel that produce both metal and rubber expansion joints that are custom-designed for specific industrial applications. By utilizing a combination of metals and synthetic elastomers, these manufacturers provide innovative solutions for a wide variety of operating environments with a high degree of reliability.

Learn more: What Are Rubber Expansion Joints? Types, Applications & Benefits

Metal expansion joints and rubber expansion joints differ primarily in how they are constructed, their maximum limits of operation, and their respective performance characteristics.

While metal expansion joints are essentially designed to carry extremely high loads at extreme operating conditions, rubber expansion joints offer the best flexibility and vibration isolation.

Metal single expansion joints are able to withstand both the highest temperatures and pressures (in addition to the maximum amount of movement) while rubber expansion joints offer superior vibration and noise reduction properties. When selecting either a rubber or metal expansion joint for a given application, one must consider the unique characteristics of that application in conjunction with its specific requirements (such as temperature, pressure rating, media type.)

When comparing metal and rubber expansion joints, the metal option offers the least amount of expansion due to temperature; therefore it can be used in high-temperature applications such as steam and exhaust systems. On the other hand, rubber expansion joints have the highest capacity for absorbing vibration or sound because of their elastic nature (due to their elasticity).

The use of rubber expansion joints should only be applied in low-pressure piping systems, while metallic universal expansion joints are intended for high-pressure piping systems. Similarly, chemical resistance varies between each type of expansion joint, according to the material(s) used to manufacture them, thus each type of expansion joint may be made compatible with different types of fluids by utilizing appropriate material(s).

Metal expansion joints have the highest temperature resistance, temperature resistance, manufacturing durability, and best operating capacity out of all the types of available expansion joints. Because of this, they can be used successfully for steam (and hot gas) applications as well as very high level of aggressive manufacturing processes. In addition to this, flexible metallic joints have been produced to extremely close tolerances, giving the industrial piping industry great benefits when requiring extremely high precision in the construction of the components they require. Contact me if you have questions about any aspect of your workplace. Metal expansion joints have a long-lasting, reliable product design and are ideal for instrumentation and other applications where failure is not acceptable.

There are many advantages of using rubber expansion joints on many different types of applications. One major advantage is that they are able to absorb vibration and noise. Rubber expansion joints are also flexible; and therefore easy to handle and work with, which makes them an excellent choice for many applications because they are light, easy to install and inexpensive. In addition, the vibration dampening characteristics of rubber single sphere expansion joints provide mechanical support by isolating the vibration from pumps, compressors, and valves. Furthermore, rubber expansion joints are compatible with multiple types of elastomers and can therefore provide good resistance to water, air, and certain chemicals.

Metal expansion joints have a reputation for being very strong, but they can also be more expensive than rubber expansion joints, and they need to be installed correctly. If not supported properly, metal expansion joints can transfer vibrations and cause issues.

Rubber expansion joints do have limitations with regard to both maximum operating temperature and maximum pressure rating; rubber expansion joints made from natural rubber can fail prematurely if they are used above their maximum operating temperature or if they are exposed to sunlight (UV radiation) or other incompatible chemicals. It's important to think about how you will use rubber expansion joints before choosing which type is best for you.

Research on operating conditions relevant to your application is necessary to choose the apt expansion joint. This includes consideration of the type of fluid you'll be using (liquid or gas), the pressure and temperature of the fluid, and how much movement (expansion or contraction) you'll encounter while the joint is being used throughout its lifetime. Depending on the temperature and/or pressure extremes of the fluid, metal expansion joints would be the best choice. Another item to consider is using rubber expansion joints to isolate the system from vibration, depending on the application.

Find out how to move liquids and gases using an expansion joint and determine how big the area will be for the physical size of the expansion joint. Look into how frequently you need to maintain the expansion joint so that it meets all applicable code requirements and/or industry standards.

If you have any questions regarding the application, please contact a qualified joint manufacturer such as Flexibel for expert assistance in selecting the proper expansion joint to ensure optimal safety, functionality, and longevity of the joint.

Pipe Systems in Industry utilize two major types of expansion joints: Metal and Rubber Expansions. Metal Expansion Joints are exposed to severe conditions, thus, giving them strength and longevity. Additionally, metal expansion joints can withstand very high temperatures, making them an excellent choice for several industrial applications. Rubber Expansion Joints can provide many benefits, including being flexibly designed, providing methods to control vibration, and having an easier install process when compared with other types of expansion joints created from metals.

Both types of expansion joints offer their own advantages and disadvantages. The selection of the best type of expansion joint for your piping system should take into consideration the conditions in which it will be installed, as well as how long you expect the joint to last. The proper engineering of an expansion joint will allow you to operate your piping systems safely and economically and reliably.