In the modern industrial society, pipelines are subject to constant stress. There are many variables involved such as temperature, changes, vibration and pressure surges that can damage a rigid system. This is where rubber expansion joints are utilized. Rubber expansion joints act as a flexible connector to absorb movement, dampen vibration and protect piping systems in the marine, oil and gas, power, water treatment and chemical processing industries.

What Are Rubber Expansion Joints?

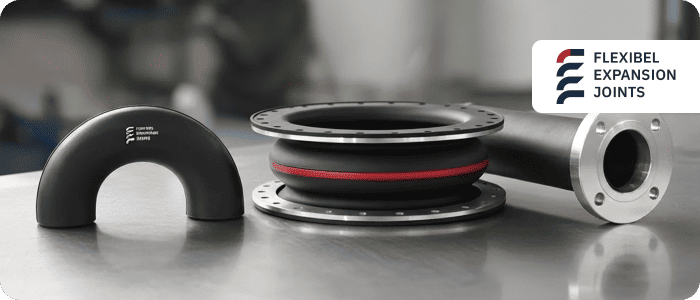

rubber expansion joints are flexible couplings that consist of elastomers (either natural rubber or synthetic rubber) and reinforced by fabric, metal, and/or wire. Most rubber expansion joints are used to absorb thermal expansion, vibration, and mechanical movement and to minimize stress and wear on connected piping and equipment.

Rubber expansion joints are well suited for use in piping systems that transport water, oil, chemicals or gases, and are particularly useful in systems designed to allow industrial rubber joints to handle continual motion or additional load induced by vibration. rubber expansion joints can also serve to buffer rigid components, preventing potential repairable or unrecoverable damages, such as cracking, leaking, or even failure of equipment.

How Rubber Expansion Joints Work

A rubber expansion joints operates under pressure, varying temperature, or mechanical movement by flexing. The elastomeric body stretches, compresses, or twists absorbing stress while minimizing strain on the adjacent pipe and connected equipment.

For example, the usage of rubber expansion joints for pumps and compressors, isolate vibration, deaden noise, and reduce wear on mechanical seals. Marine and industrial rubber expansion joints add flexibility to protect the pipeline from shock, corrosion, and misalignment, creating a more civilized operating situation in harsher environments.

See Also: Your Guide to Metal Expansion Joints: Design, Uses, and Advantages

Types of Rubber Expansion Joints

There are multiple types of expansion joints that provide excellent benefits, depending on what the needs of a particular system are:

- Single Bellows Rubber Expansion Joint - Compact and efficient, appropriate for moderate pressures and smaller pipelines. Axially, laterally, and angularly flexible.

- Rubber Twin Sphere Expansion Joint - Designed to absorb more movement and vibration. Typically used in industrial pipelines with a need for significantly more flexibility.

- PTFE-Lined Rubber Expansion Joint - Ideal for corrosive or chemical applications, PTFE-lined joints provide excellent resistance, durability, and reliable sealing performance under pressure.

- Reducer Expansion Joint - Used to connect pipes of different diameters, reducer joints absorb movement, reduce stress, and maintain pressure balance in piping systems.

- Clamp-Type Expansion Joint - Easy to install and maintain, clamp-type joints offer flexibility and vibration control in low-pressure applications across multiple industries.

- Flanged Rubber Expansion Joints - Has metal flanges for attachment points to ensure secure installation. Typically used in rubber expansion joints for pumps and compressors.

- Arch-Type Rubber Expansion Joints - Curved, allowing for greater movement and vibration absorption than traditional bellows types. Typically used in HVAC systems and water treatment systems.

- Spherical Rubber Expansion Joints - Compact, durable, and meant for chemical, maritime, industrial applications.

- Rubber Expansion Joints & Bellows - A combination of flexibility and vibration control. This is the best choice in complex piping systems that have multi-dimensional movement.

Flexibel Expansion Joints is a trusted rubber expansion joint manufacturer in UAE that makes custom expansion joints for all of these types of applications while ensuring every joint meets your industrial and environmental needs.

Applications of Rubber Expansion Joints

Rubber expansion joints can be used in various industries:

- Power Plants: Handle thermal expansion in steam and cooling piping.

- Water & Wastewater Treatment: Alleviate stresses in piping from photorealistic pump vibrations.

- Marine Industry: Resist seawater corrosion and for use in engine rooms.

- Chemical Plants: Accommodate heavy fluids without breakdown.

- HVAC Systems: Isolate noise and vibration in air-handling units.

- Oil & Gas Pipelines: Maintain system integrity at high temperature and high pressures.

By absorbing movement and providing vibration mitigation; enhanced safety, reliability, and performance are the result. These benefits make rubber expansion joints vital throughout various industries in the Middle East and Europe.

Read More: Expansion Joints: Custom Solutions for Industrial Applications

Benefits of Rubber Expansion Joints

The application and economic advantages offered by rubber expansion joints are numerous.

- Vibration and noise reduction: By isolating vibration caused from the operation of pumps, compressors, and rotating equipment, rubber expansion joints mitigate noise within industrial plants while enhancing the protection of sensitive equipment. This leads to reduced downtime and maintenance costs.

- Thermal expansion compensation: Rubber expansion joints are designed to absorb axial, lateral, and angular movement due to temperature variation. They relieve stress on piping systems eliminating the potential of cracking or leaking.

- Corrosion and chemical resistance: The rubber elastomers employed in the production of rubber expansion joints (EPDM, Nitrile, or Neoprene) increase resistance to chemical damage as well as saltwater corrosion; ideal for both marine and industrial rubber expansion joints.

- Equipment lifespan: Mechanical stress is minimized on piping systems with rubber expansion joints, providing added protection to valves, pumps, compressors, and piping which extends the life of the overall assembly.

- Easy installation and replacement: The flexible elastomeric design of the rubber expansion joint allows for an ease in installation, aligning, and replacing the component. This can be a huge savings in labor and time.

- Versatile across industries: Rubber expansion joints can serve multiple applications in various fields such as water treatment, oil and gas, HVAC, and chemical amongst many others including rubber expansion joints for pumps and compressors.

Prioritizing premium rubber expansion joints into your operation will improve efficiency and safety while increasing your return on investment for your respective industry.

Factors to Consider When Choosing the Right Rubber Expansion Joint

Choosing the right rubber expansion joint involves evaluating several factors:

- Pressure & Temperature Ratings: The joint must accommodate the system pressure and the operating temperature. Reinforced types should be used for high-pressure applications, while standard bellows can be used for moderate pressures.

- Movement Requirements: Identify the required movement for axial (length), lateral (side-to-side), or angular (twist). If the type of movement is missed, the joint will fail prematurely.

- Chemical Compatibility: Different elastomers respond differently when exposed to fluids. EPDM is water and steam resistant, Neoprene can resist oils, nitrile is fuel and solvent resistant, etc. Selecting the proper material will mitigate degradation and fluid leaks.

- Pipe Size & Connection Type: Selecting the proper size will ensure joint stress is minimized. Connection types can be flanged, grooved, or spigot, which must fit the system correctly.

- Environmental Considerations: UV exposure, ozone, ambient temperature, and vibration levels should all be considered. A protective cover or shield may be necessary in harsh environments.

- Manufacturer Experience: An experienced rubber expansion joint manufacturer will have engineering precision control and long-term reliability. This is especially true when working with a UAE-based manufacturer & service provider of rubber expansion bellows like Flexibel Expansion Joints which can satisfy industrial standards.

By taking these considerations into account industrial managers will ensure that their expansion joints will sustain a long life while also maximizing safety and reliability.

Rubber Expansion Joints Installation and Maintenance Tips

Proper installation and regular maintenance of expansion joints and rubber bellows are essential for best performance. Correctly align, as misaligned joints can cause stress, reduce flexibility, and reduce service life. Use proper installation tools and specifications for torque as specified by the manufacturer.

- Avoid Overextension and Torsion: Exceeding the allowed movement will damage the elastomer. Make sure that the joints are not stretched or twisted beyond the rated movement.

- Inspect Regularly: Check routinely for signs of cracking, leaking, bulging or soft spots. Finding issues early can mitigate failure and cost.

- Protect Environment: Protect joints from UV light, chemicals and extreme heat. Special covers can increase performance life.

- Clean Up Area: Prevent debris, dirt and chemical deposits from getting between performances or damaging the joint surface.

- Lubricate and Support: In some high vibration applications adding supporting hardware or using vibration isolators can lessen stress.

Learn More: Quality Manufacturer of Bellow Expansion Joint for Modern Industries

Common Issues and How to Avoid Them

- Misalignment: Causes stress and cracking.

- Solution: Installation should be as designed.

- Overpressure: Can cause bellows deformation.

- Solution: Use joints certified for system pressure.

- Chemical Attack: Elastomer not compatible with fluid.

- Solution: Right material should be selected.

- Excessive Vibration: Lessens life.

- Solution: Add vibration isolators, if necessary.

Why Rubber Expansion Joints by Flexibel are Ideal for Industrial Applications

Flexibel is a manufacturer of expansion joints in the UAE and trusted across GCC areas like Saudi Arabia, Qatar, Bahrain, and Kuwait. The industrial environment specifies the design of flexible, durable and high-performance durable and flexible joints:

- High Temperatures: Because pipelines are typically transporting hot fluids, it is important that the joints can accommodate thermal change in size without failure.

- Harsh Conditions: Due to high UV, humidity and sand exposure, lesser grades of materials can lose their qualities rapidly. Top grade elastomers will have a longer lifespan against those conditions.

- Vibration and Movement: Pumps, compressors, and HVAC systems are all being used in a constant vibrating environment, and flexible joints will allow the systems to run longer with less wear and noise.

- Chemical Exposure: There are many oil and gas, desalination, and industrial chemical industries in the Gulf. These materials all pose a threat for corrosion of lesser grade materials.

Flexibel Expansion Joints designs custom rubber expansion joints, specifically for this region of the world to ensure safety, efficiency, and reliability. Joints are designed with durability, flexibility, and long-term performance as the primary criteria making them a highly regarded solution in the industrial environment of the region.

Why Choose Flexibel Expansion Joints

Flexibel Expansion Joints, a leading Rubber Expansion Joints Manufacturer in UAE provides unrivaled workmanship and top-of-the-range solutions, including:

- Custom Manufacturing: Expansion joints customized to meet the precise requirements of pumps, compressors, chemical pipelines, and marine applications.

- High Quality Materials: Products designed with only quality elastomers and reinforcement components to ensure they perform and withstand service in harsh condition and application environments.

- Global Standards: Our products are manufactured to comply with global iii quality standards for industrial, marine and chemical applications.

- Expert Technical Support: Flexibel eases the process of selection, installation and maintenance, enabling customers to exceed system expectations and performance.

- High quality Expansion joints and Rubber Bellows: Reliability comes down to quality, customized solutions and expert knowledge.

Flexibel Expansion joints provides reliable, high-performance solutions for different types of industries within the UAE, Italy, Spain and the Gulf, developed for multiple operational environments