Today's industrial, commercial, and infrastructure systems have many pipes within their networks and must therefore operate smoothly under the impact of constantly changing pressure, temperature, vibration, and structural movement.

To achieve such flexibility within these piping networks, flexible pipe connectors become an essential element. Flexible pipe connectors will provide a means for absorbing movement, reducing stress, and providing long-term protection for your piping systems.

In many industries, such as Gas, Marine, HVAC (Heating, Ventilation, Air Conditioning), Power Generation, Chemical Processing, and Manufacturing Centres, the reliability of a piping system is directly linked to how well the flexible connection within that piping system is made. Whether it be for handling thermal expansion and contraction, isolating vibration, or accommodating misalignment, the use of flexible pipe connectors serves to improve equipment life and improve overall efficiency of the piping system.

Flexible pipe connectors provide versatility and ease of installation for any application, from residential plumbing to fully integrated industrial operations. The following covers all that you need to understand the use of flexible piping connections by detailing their types, benefits, applications, methods for selecting them, and related difficulties associated with their use.

Flexible pipe connectors are custom-designed parts that join two rigid piping sections together to absorb the movement induced by the heating and cooling process, mechanical vibration, backpressure, and misalignment from the way the piping was assembled. By absorbing such movements, flexible connectors protect pipes, valves, pumps, and other types of connected equipment from experiencing excessive stress, which might otherwise cause leaks or premature failure.

Piping systems found in industrial applications tend to be very dynamic in nature. Pipes expand when heated and contract when cooled; rotational equipment causes vibrations to pass through pipes; and misaligned piping may be a result of external forces such as worker activity or equipment movement. Without a properly designed flexible connection, the forces generated by these activities could be passed on to the other components in the piping system, resulting in any number of potential problems, such as leaks, cracks, or even equipment failure.

As we discussed previously, manufacturers like Flexibel Expansion Joints will engineer flexible connectors for a specific application and design them for high performance, durability, and longevity in industrial environments.

See also: Importance of Fabric Expansion Joints in Industrial Applications

Flexible Pipe Connectors come in many designs and are made with each one designed specifically for one set or type of environmental operating condition. To properly select the correct connector for any application, you must first determine the following items: the application pressure and temperature(s), the type of movement, and the primary material(s) being transferred through the connector.

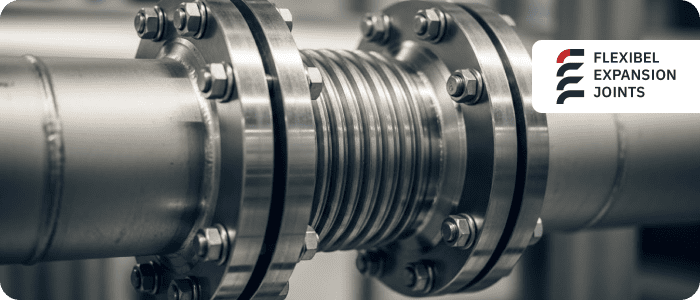

Metal flexible Pipeline Connectors are made specifically for use with high-pressure/high-temperature conditions. They are usually made from stainless steel, and many will also include metallic expansion joints, which allow the connectors to accommodate axial, lateral, and angular movements.

Metal flexible pipeline connectors are most commonly used in power plants, refineries, steam lines, and industrial piping systems, where a product must be strong and durable. When compared to Non-Metallic Pipe Connectors, Metal Connectors provide significantly greater resistance to Pressure, Fire, and High Temperatures while also providing Flexibility.

The rubber flexible pipe connectors are designed to reduce vibration and noise. Rubber flexible pipe connectors are often applied in conjunction with rubber expansion joints installed within HVAC systems, water pipelines, pumping connections, and wastewater treatment plants/radiation plants, as well as many industrial businesses/companies.

Rubber flexible pipe connectors are flexible, resilient, corrosion-resistant, and capable of mitigating mechanical vibration. Rubber flexible pipe connectors are particularly beneficial for low- and medium-pressure systems that require chemical compatibility and the capability of absorbing movement.

Fabric flexible pipe connectors are non-metallic, lightweight products used for the movement of large amounts of thermal energy and the expansion of ductwork (e.g., duct, flue gas, etc.). They provide excellent flexibility when installed in the ductwork of an exhaust system.

Fabric connectors are also commonly found in high-temperature applications, where the use of metals may not be feasible or safe due to a variety of chemical and corrosive conditions associated with a variety of systems.

Because they are made of multiple layers, fabric connectors can accommodate complex movements in addition to being resistant to chemical and corrosive gas exposure.

Composite flexible pipe connectors combine several different materials to give them both chemical resistance, flexibility, and lightweight construction. These composite flexible pipe connectors are commonly used in the process of unloading and loading liquids or gases from tankers. Composite flexible pipe connectors also contain integrated fabric expansion joints or rubber expansion joints to provide enhanced performance.

Composite flexible pipe connectors are ideally suited for transporting aggressive chemical products in marine environments, and in applications where there is a need for continuous movement while providing so much safety.

flexibel pipe connectors can help to lower the mechanical stress in piping systems. They absorb vibration, thermal expansion, and surge pressure so damage does not occur to the piping systems due to these movements.

Flexible connectors allow for the extension of the service life of pipes, pumps, and valves by isolating sensitive components from the operational forces of the piping system. Flexible connectors also help to improve system safety and reduce maintenance costs, and result in quieter, smoother operation.

See also: Exploring Different Types of Metal Expansion Joints

Flexible pipe connectors are utilized in many different types of industry and, as a result, can reduce vibration transfer from equipment to the ducting within HVAC systems and allow for movement due to waves and structural movement in marine and offshore environments.

In industrial applications, flexible pipe connectors are integrated into pipeline systems transporting steam, chemicals, water, gas etc. Flexible connectors are used extensively in power generation, desalination, and manufacturing operations where piping systems experience continuous stress.

To properly select flexible pipe connectors, you need to know the working environment. You must look at the operating pressure, temperature, and types of motion for your application.

You also need to consider what materials will work best for those given environments. For example, metal flexible pipe connectors are the best choice for the most severe environments. Whereas, rubber flexible pipe connectors and fabric flexible pipe connectors provide excellent vibration dampening and chemical resistance. Consultation with experienced manufacturers such as Flexibel Products will ensure that your connector is manufactured at the correct size, engineered for your application, and complies with applicable industry requirements.

See also: Your Guide to Metal Expansion Joints: Design, Uses, and Advantages

Flexible pipe connectors typically experience issues due to improperly installing flexibel pipe connectors. Similarly, if flexibility products are not installed correctly due to misalignment, overstretching, or poor support, flexible pipe connectors will not perform as designed and will fail prematurely. Additionally, selecting the incorrect material for an application may result in either a chemical breakdown or failure of the product.

Scheduled check-ups of flexible pipe connectors, proper anchoring, and the selection of flexible pipe connectors according to the operating conditions for which they were designed can minimize or eliminate issues and provide longer-lasting performance and reliability.

Flexible pipe connectors are integral components of all current piping systems. As they mitigate, absorb, and protect against vibration and movement, flexible pipe connectors are one of the most important components in ensuring the effectiveness and safety of the entire piping system.

The term 'flexible pipe connectors' includes both metallic expansion joints, rubber expansion joints, and fabric expansion joints. Selecting the best type of flexible connector will provide greater efficiency, reduce maintenance costs, and increase your overall utility longevity. A good and properly designed flexible connector can be sourced from a reputable provider like Flexibel. Flexible pipe connectors will continue to provide support for reliable operations in many industries.